LB990 High Speed Paper Cup Machine

LB990 High Speed Paper Cup Machine

Introduction:

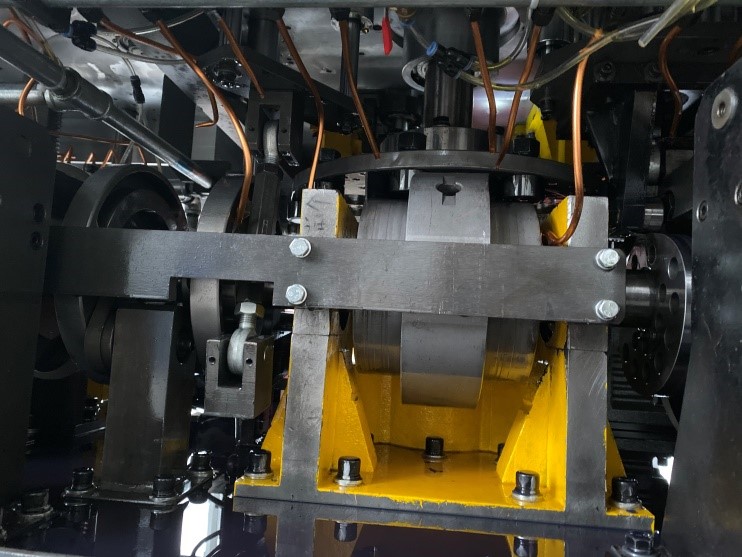

Our newly designed LB 990 paper cup forming machine is a fully automatic paper cup forming machine, which can produce different sizes of paper cups with a series of continuous process, including automatic paper feeding, paper anti-withdrawal device (to ensure accurate positioning), ultrasonic welding, transferring paper fan by robot hand, silicone oil lubricating, bottom punching, bottom folding, bottom pre-heating, bottom knurling, cup discharging. The machine, researched and developed by our company, is improved steadily after comprehensive technical improvements.

Sample Made From Machine:

Main Features:

1. Bottom sealing by hot air devices, so that the machine is efficient, the hot air device is imported from Switzerland.

2. And cup side sealing by ultrasonic.

3. More efficient and higher performance.

4. Cup top curling and bottom knurling are finished by separate turn-plates.

5. It is easy to make cups with different sizes by changing moulds.

6. With automatic cup delivery system with counter.

Technical Specification:

Model | LB 990 |

Cup Size | 3oz ~42oz |

Raw material | 190~350gsm Single or Double PE coating paper |

Output | 120~150pcs/ minute(Cup); 90~110pcs/min(Bowl) |

Electrical requirement | 380V, 3-phase |

Working Power | 18KW |

Air Specification | 0.5~0.8Mpa, 0.4m^3/min |

Configure Power | 21KW |

Packing dimension | L2900mm×W1380mm×H1800mm |

Machine Weight | 5000 kgs |

Cup Use | round paper cups, drinking , noodle and vending cups ice-cream and food containers |

Leading Technology:

Adopts rotation type paper feeding type instead of previous pendulum type paper feeding type:

Advantage:

(1). Prevent dust and wastepaper from entering the lubrication system;

(2). The rotation is more stable while the pendulum is too long and easy to shake.

Box type open cam drive system with double longitudinal axis, all cams adopt 20CrMnTi numerical control (Nc) machining to do precision grinding.

Main Parts Brand List:

Item No. | Item | Brand | Origin |

1 | Linear Bearing |  | TAIWAN |

2 | Joint Bearing |  | JAPAN |

3 | Other Bearing |  | JAPAN |

4 | Cam Actuator |  | JAPAN |

5 | PLC |  | JAPAN |

6 | Servo Motor |  | JAPAN |

7 | Main Electrical Component |  | JAPAN |

8 | Motor | WANSHSIN | CHINA |

9 | Heater | WELLRE | CHINA |

10 | Pneumatic Component |  | JAPAN |

11 | Screw Bolt | 12.9 degree high strength screw bolt | CHINA |