LB-ZB9 Paper Cup Machine

LB-ZB9 Paper Cup Machine

Introduction:

The new paper cup forming machine is a fully automatic paper cup forming equipment, through multi-row automatic paper feeding, paper anti-return device (to ensure accurate positioning), ultrasonic welding or electric heating welding, oil injection, mechanical hand paper tube transfer, cup feeding, punching bottom, bottom folding, preheating, knurling, hemming, cup closing and other continuous processes can stably produce paper cups of various specifications.

Technical Specification:

Model | LB-ZB9 Model |

| |

Weight | 1100KG | ||

Specification | 2200x1100x1400 | ||

Power | 380V,3 Phase 4.5KW | ||

Capacity | 70-80Pcs/Min | ||

Paper Specification | Single PE/Double PE | ||

Paper Thickness | 150-350g/㎡ | ||

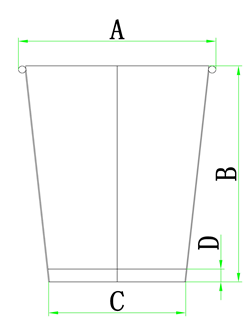

Specification | (A)φ50-75mm | (B)φ45-85mm | |

(C)φ35-60mm | (D)φ5-8mm | ||

Electric Parts | Ultrasonic | Ruian | |

Frequency | Panasnoic | ||

Sensor | Ruixiang | ||

Breaker | France Schneider | ||

Relay | France Schneider | ||

Reduction Motor | Hangzhou | ||

Main Motor | Zhejiang | ||

Turned Edge | Zhejiang | ||

Pneumatic Elements | Cylinder | Kogel | |

Mechanical Configuration | Driving Shaft | 40CR Slack Quench | |

Straight line Ray Axis | Hard Axis | ||

Grooved Sheave | Wenzhou | ||

Blade Mould/Knurling | CR12Quenching/40CR Nitridize | ||

Cam | Digital Control Processing +Nitridize | ||

Turn Tbale | Aluminum Alloy | ||

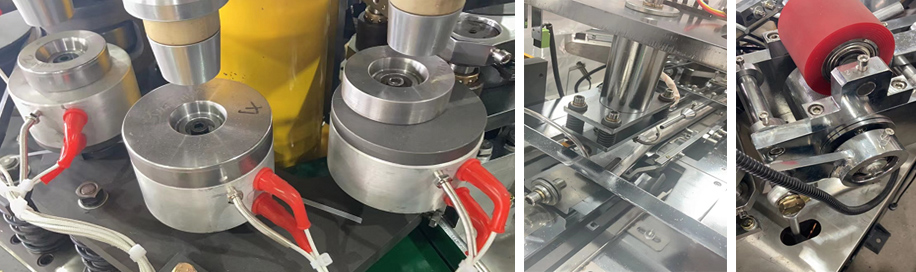

Machine Pic: